Medical IT Systems

Home - Medical IT Systems

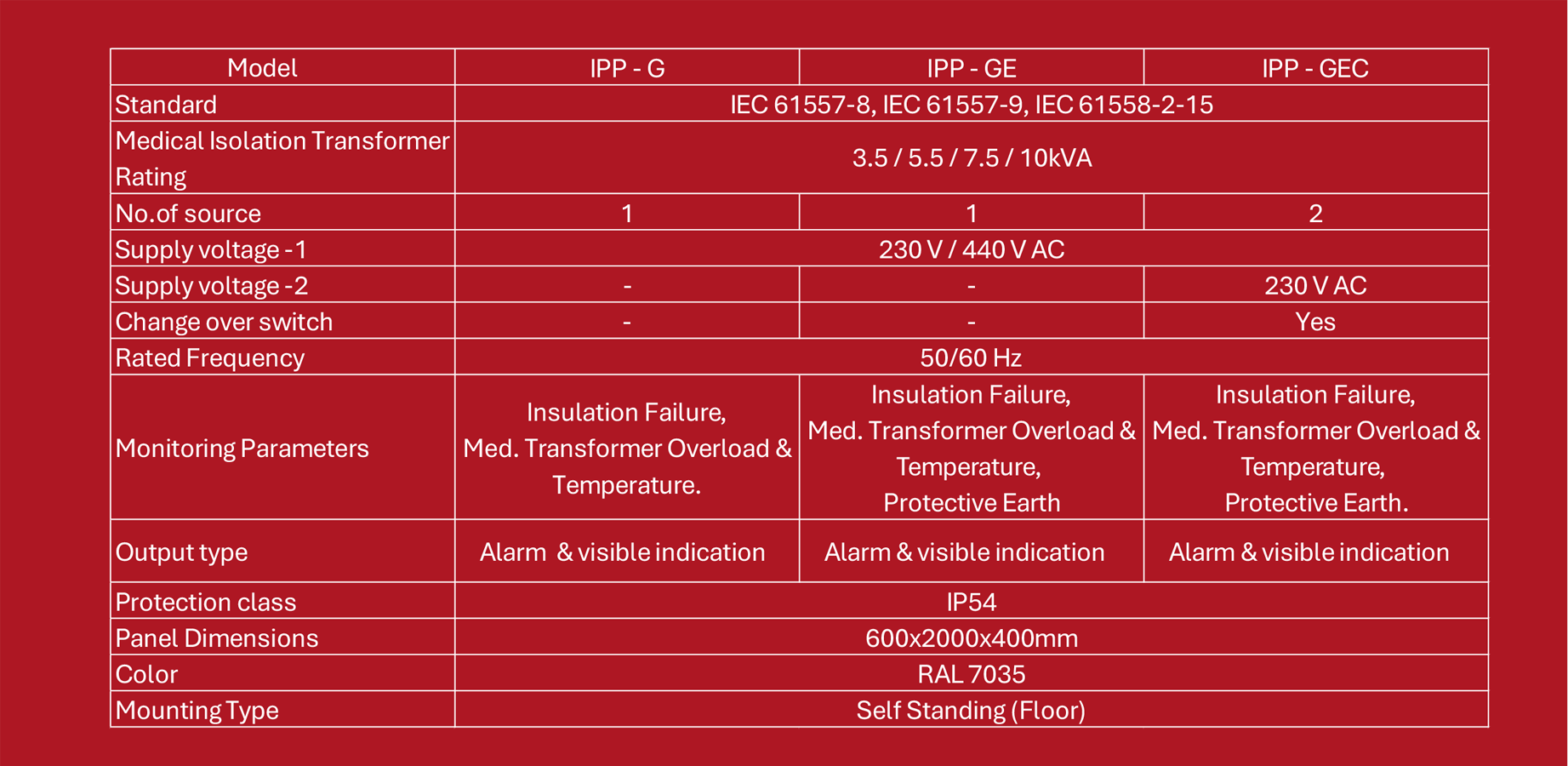

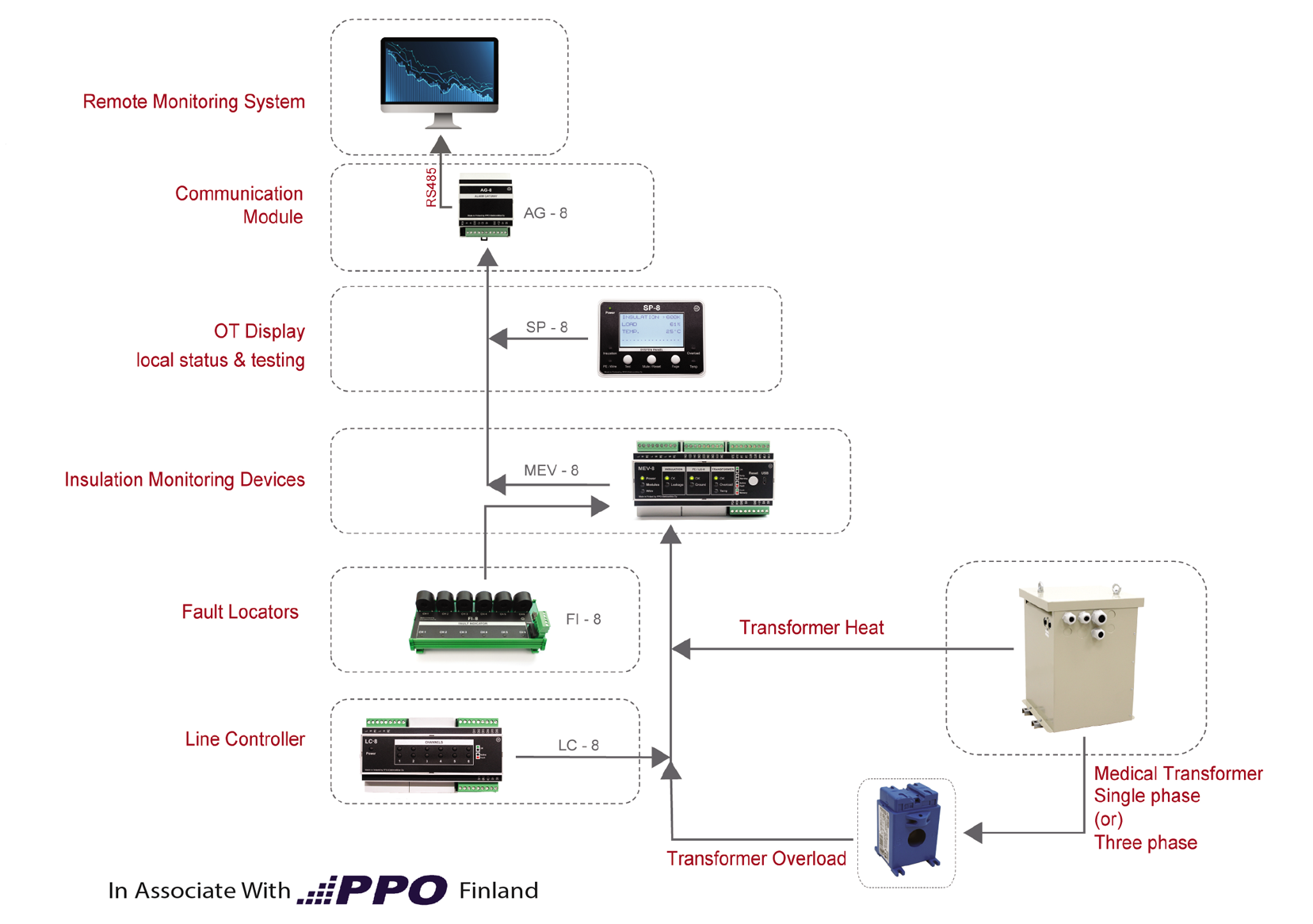

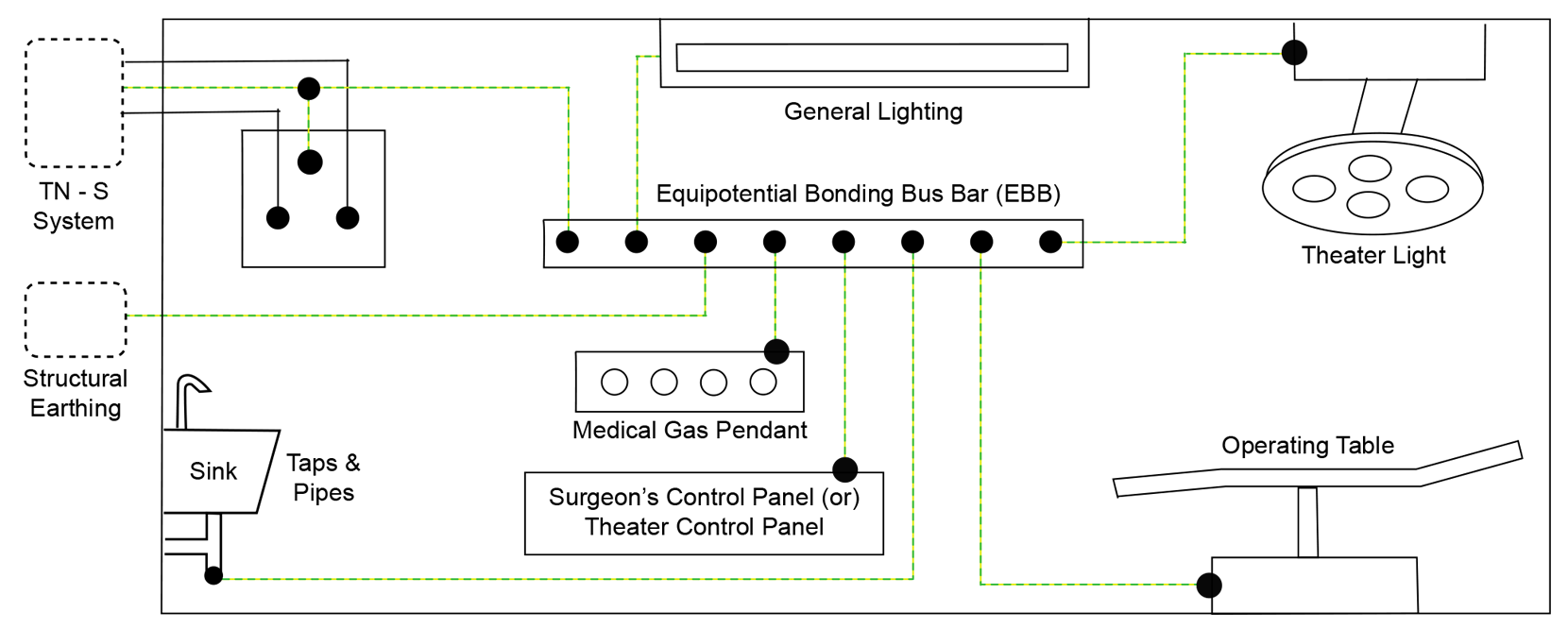

Medical IT systems, are critical safety measure for Group 2 medical locations. They ensure the continuity of power supply to critical medical equipment during first fault condition. Insulation monitoring is vital in operating rooms, as it detects and addresses electrical leakage currents caused by poor connections, damaged cables, and defective components. These systems monitor insulation levels, transformer load, and temperature, ensuring any faults are promptly managed.

Medical IT systems by CAPE significantly enhance safety by integrating various protective measures in medical locations and ensure the reliability and efficiency of critical medical equipment.

The Medical Isolation Transformer provides electrical separation from TN / TT system, minimizing shock risks and leakage currents. The MED IMD continuously checks the insulation resistance of the ungrounded system, issuing alarms once the insulation level falls below the set limit, and the remote alarm indicator promptly alerts medical staff on any issues, allowing immediate action to ensure patient safety and equipment reliability

It is a matter of safety, efficiency and cost savings